As a trusted manufacturer and exporter of premium automotive and earthmover components, Fusion Auto Forge offers a wide range of high-performance Bucket Bushes engineered for maximum durability and efficiency in heavy-duty applications.

Our bucket bushes are designed to withstand extreme operating conditions, ensuring optimal performance and longer service life in earthmoving equipment such as excavators, loaders, and backhoes.

Why Choose Our Bucket Bush?

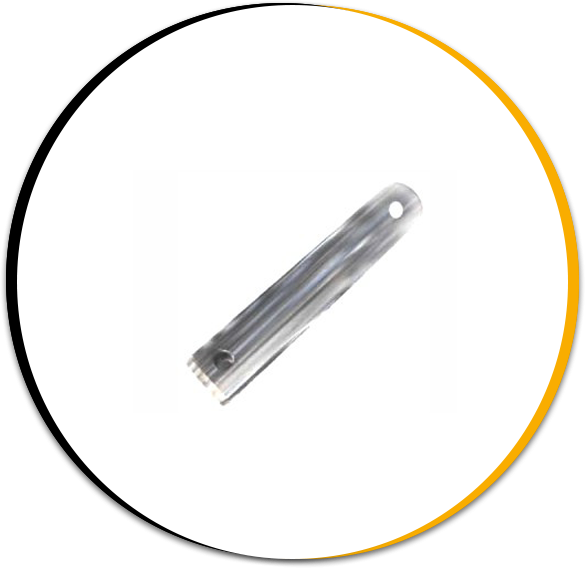

Fusion Auto Forge specializes in the manufacturing and export of premium L&T Bushes, engineered to deliver long-lasting performance and high wear resistance in L&T earthmoving equipment. Our L&T bushes are designed with precision to ensure durability, smooth operation, and a perfect fit in demanding working environments.

As a trusted name in the industry, Fusion Auto Forge delivers consistent quality and performance, supported by advanced manufacturing facilities and a strong commitment to customer satisfaction.

Why Choose Our L&T Bush?

We manufacture and export top-quality Excavator Bushes that are engineered for strength, durability, and performance in demanding work environments. Designed to reduce friction and wear, our excavator bushes ensure smooth pivoting and longer life of critical joints in heavy machinery.

With advanced machining and heat-treatment processes, our bushes deliver excellent performance under high load and extreme working conditions, making them a trusted choice for OEMs and aftermarket clients worldwide.

Why Choose Our Excavator Bush?

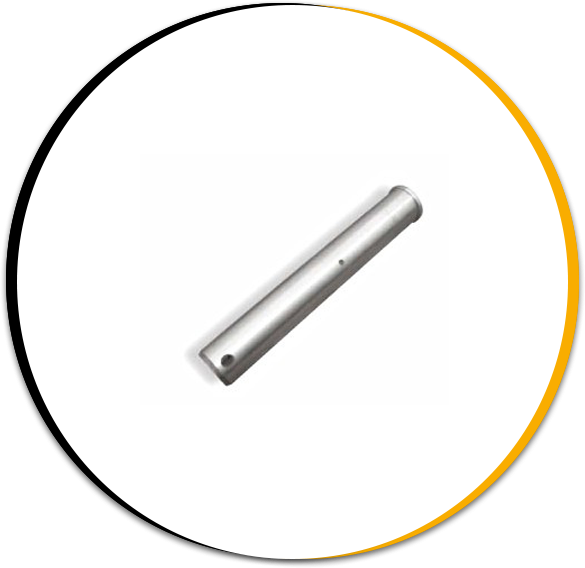

We are a leading manufacturer and exporter of high-performance Excavator Pins designed to deliver maximum strength, durability, and reliability in heavy-duty earthmoving applications. Our excavator pins are engineered with precision to ensure a perfect fit, smooth articulation, and long service life under the toughest operating conditions.

Whether you’re sourcing for OEM requirements or aftermarket needs, Fusion Auto Forge provides excavator pins that meet international standards and perform reliably in the most demanding environments.

Why Choose Our Excavator Pins?

Fusion Auto Forge is a trusted manufacturer and global exporter of precision-engineered Chain and Track Pins for a wide range of earthmoving and construction equipment. Designed to withstand high impact, abrasive conditions, and heavy loads, our pins are built for durability, smooth performance, and a longer service life.

Our Chain/Track Pins are essential components in the undercarriage system of excavators, dozers, and other tracked machinery—ensuring optimal track movement and minimizing wear over time.

Why Choose Our Chain/Track Pins?

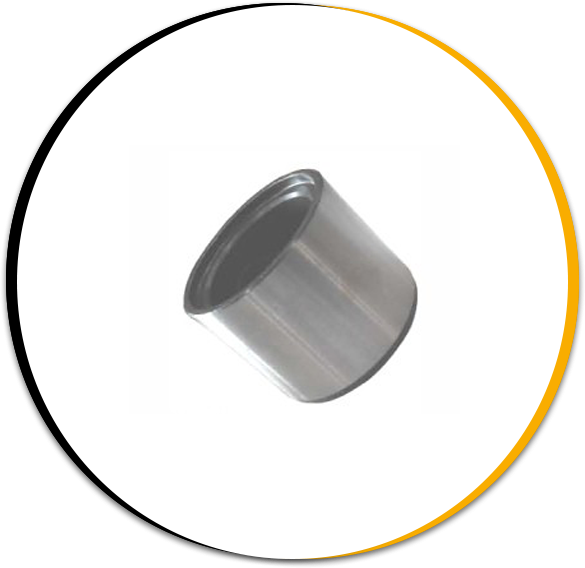

At Fusion Auto Forge, we manufacture and export high-quality Chain/Track Bushes engineered for durability, strength, and long-lasting performance in heavy-duty tracked machinery. Our track bushes play a critical role in undercarriage systems by minimizing wear and ensuring smooth articulation between pins and links in tracked equipment.

Built to withstand extreme working conditions, our Chain/Track Bushes are trusted by OEMs and aftermarket clients worldwide for their precision engineering, excellent wear resistance, and robust construction.

Why Choose Our Chain Track Bush?

At Fusion Auto Forge,is a leading manufacturer and exporter of durable and high-precision Bucket Pins, designed to deliver superior performance in demanding earthmoving applications. Our bucket pins are engineered to provide a perfect fit and long-lasting reliability, even under extreme load and continuous usage.

With advanced manufacturing processes and stringent quality control, we ensure that every pin meets international standards and supports the optimal operation of your heavy machinery.

Why Choose Our Bucket Pin?

We specialize in manufacturing and exporting high-strength Terex Dipper Pins, engineered to meet the exact specifications of Terex equipment. Designed for durability and precision, our dipper pins ensure smooth operation, reduced wear, and extended service life in tough earthmoving and construction environments.

Each Terex dipper pin is built using premium-grade materials and undergoes advanced heat treatment to withstand high loads, continuous motion, and harsh working conditions.

Why Choose Our Terex Dipper Pin?

Fusion Auto Forge is a trusted manufacturer and exporter of high-performance Terex Loader Pins, built to deliver unmatched strength, durability, and precision for heavy-duty Terex machines. Our loader pins are engineered to meet or exceed OEM specifications, ensuring a perfect fit and reliable operation in even the toughest working environments.

Crafted from high-grade materials and treated for enhanced wear resistance, our Terex loader pins are designed to reduce downtime and extend the service life of your equipment.

Why Choose Our Terex Loader Pin?

Fusion Auto Forge, we manufacture and export premium-quality KPC Pins designed for strength, precision, and long-term performance in demanding earthmoving applications. Engineered to exact specifications, our KPC pins are widely used in a variety of heavy machinery, ensuring smooth operation, reduced wear, and dependable durability.

Manufactured using top-grade materials and advanced heat treatment processes, our pins are built to withstand high impact, continuous movement, and tough working conditions.

Why Choose Our KPC Pin?

At Fusion Auto Forge, we manufacture and export high-precision Escort BKT Pins that are built to deliver exceptional performance and durability in a wide range of Escort earthmoving and backhoe loader applications. Designed with a focus on strength, reliability, and perfect fitment, our BKT pins are ideal for heavy-duty working conditions.

Crafted using premium raw materials and advanced heat treatment techniques, our pins ensure reduced wear, smooth articulation, and longer service life for Escort machines operating in rugged environments.

Why Choose Our Escort BKT Pin?

At Fusion Auto Forge,is a leading manufacturer and exporter of high-performance TATA JD Pins, engineered to meet the precise requirements of TATA JD backhoe loaders and construction equipment. Built for durability and long service life, our pins ensure smooth movement and optimal alignment even in the most demanding job site conditions.

Crafted from high-grade materials and treated with advanced hardening processes, our TATA JD pins provide exceptional resistance to wear, corrosion, and mechanical stress, making them ideal for both OEM and aftermarket use.

Why Choose Our TATA JD Pin?