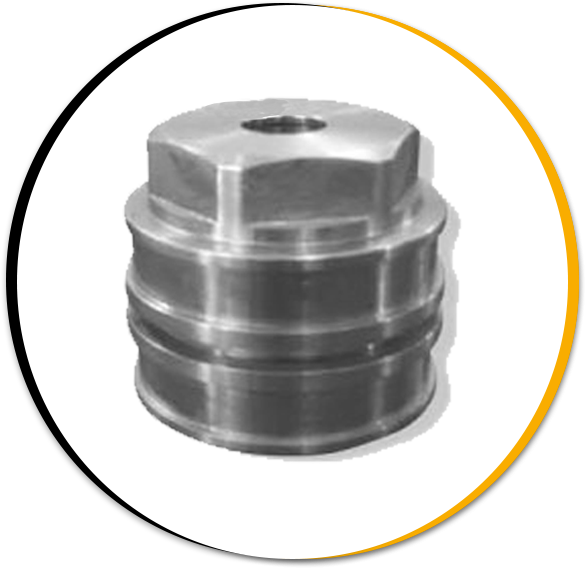

We specialize in the design and manufacture of high-performance slew pistons engineered for precision, durability, and reliability. Slew pistons play a critical role in enabling the controlled rotational movement of heavy machinery and equipment such as cranes, excavators, drilling rigs, and marine systems.

Our slew pistons are built to withstand high pressure and harsh working environments, ensuring smooth slewing motion and accurate positioning under load. Whether for construction, industrial, or offshore applications, our solutions are tailored to meet your operational demands.

Used widely in excavators, cranes, and hydraulic systems, our slew pistons are crafted to deliver optimal efficiency, power transmission, and wear resistance.

Why Choose Our Slew Pistons?

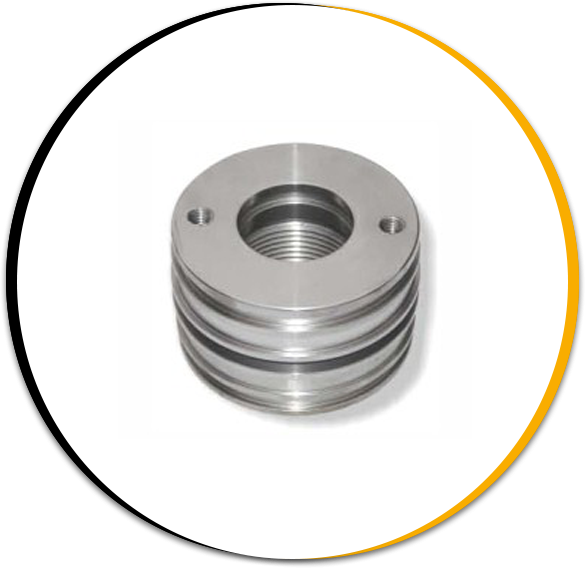

At Fusion Auto Forge, we specialize in the production and export of durable, high-performance Dipper Pistons designed for heavy-duty earthmoving machinery. Engineered with precision and manufactured using high-grade materials, our dipper pistons deliver the strength and reliability needed to perform in the most demanding environments.

Dipper pistons are a critical component in backhoe loaders and excavators, enabling the smooth and powerful movement of the dipper arm. Our pistons are crafted to ensure optimal hydraulic performance, extended service life, and minimal downtime.

Whether for OEM replacements or custom solutions, Fusion Auto Forge is committed to delivering piston components that meet international quality standards and keep your operations running smoothly.

Why Choose Our Dipper Piston?

We design, manufacture, and export high-quality Bucket Pistons engineered to meet the intense demands of earthmoving and construction machinery. Our pistons are built for strength, durability, and smooth hydraulic operation, delivering powerful performance where it matters most — at the bucket.

Bucket pistons play a crucial role in the operation of excavators and loaders, controlling the bucket’s movement and ensuring efficient digging, lifting, and dumping. Our components are manufactured using advanced materials and processes, guaranteeing optimal performance and long service life even under extreme conditions.

Whether you’re looking for dependable OEM replacements or custom-built solutions, Fusion Auto Forge is your trusted source for bucket pistons that deliver consistent, reliable performance — every time.

Why Choose Our Bucket Piston?

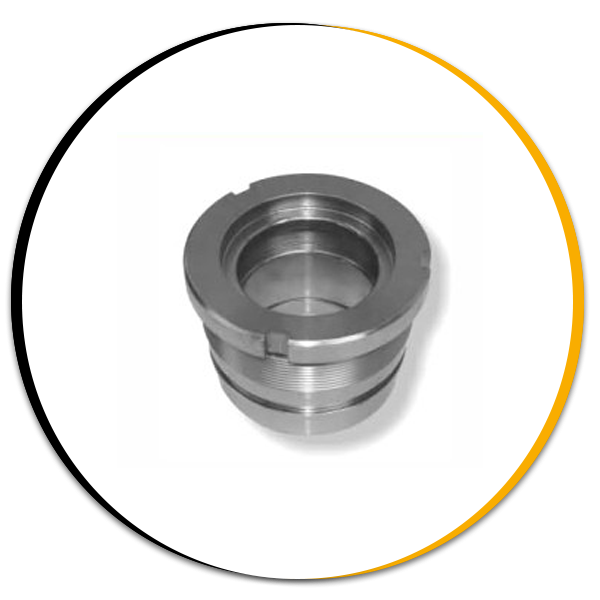

We manufacture and export premium-grade Bucket Glands designed to deliver superior sealing performance in heavy-duty hydraulic systems. Engineered for durability and precision, our bucket glands are a critical component in the operation of excavators, loaders, and other earthmoving machinery.

Built to withstand high pressures, extreme conditions, and continuous use, our glands ensure optimal sealing of hydraulic cylinders reducing leakage, extending equipment life, and improving overall machine efficiency.

Whether you’re servicing OEM equipment or customizing parts for specific projects, Fusion Auto Forge, provides bucket glands you can rely on — every time, everywhere.

Why Choose Our Bucket Gland?

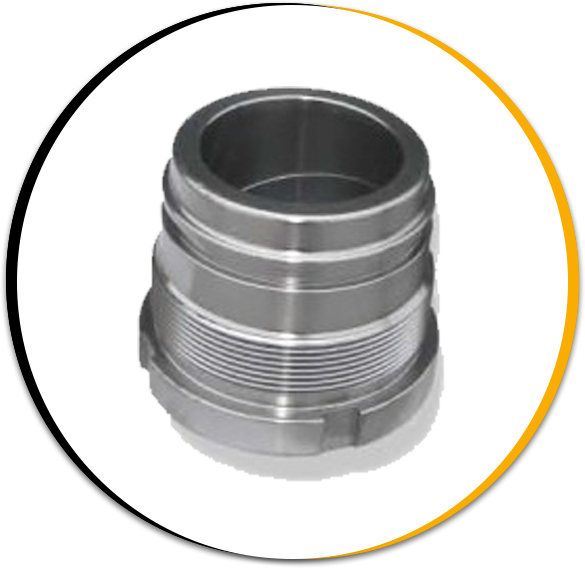

We are proud to offer high-performance Stabiliser Glands designed to ensure leak-proof operation and long-lasting durability in demanding hydraulic systems. As a leading manufacturer and exporter of quality components for earthmoving and heavy machinery, we understand the importance of precise sealing in stabiliser cylinders — where strength, reliability, and endurance are key.

Our stabiliser glands are engineered to handle extreme working conditions, maintaining efficient hydraulic pressure while preventing contamination and fluid leakage.

When it comes to stabiliser performance, a reliable seal makes all the difference. With Fusion Auto Forge, you get sealing solutions that keep your machines grounded — and your operations moving forward.

Why Choose Our Stabliser Gland?

At Fusion Auto Forge, we specialize in producing and exporting Dipper Glands that ensure superior sealing performance in hydraulic systems for heavy-duty machinery. Designed for the dipper cylinders of excavators and backhoe loaders, our glands are engineered to deliver durability, high-pressure resistance, and extended service life.

Our dipper glands are crafted using premium materials and precision machining techniques, ensuring a perfect fit and optimal performance even under the most challenging operating conditions. Whether you’re maintaining OEM equipment or customizing solutions, our glands provide the sealing integrity your machinery depends on.

With Fusion Auto Forge, you’re not just getting a part — you’re getting a commitment to quality, performance, and reliability.

Why Choose Our Dipper Gland?

We manufacture and export premium-quality Hook Pins that deliver unmatched strength, precision, and durability in demanding earthmoving and construction applications. Designed to secure and support key components in heavy machinery, our hook pins are engineered to handle high loads and repeated use without compromising performance.

Whether used in buckets, linkages, or quick couplers, our hook pins ensure a tight, secure connection that supports smooth machine operation and extended service life.

As a trusted name in the global market, Fusion Auto Forge delivers hook pins that are built to perform and made to last — wherever strength and reliability matter most.

Why Choose Our Hook Pin?

We manufacture and export high-quality King Pins (N/M – Non-Machined or Machined) designed to ensure the strength, stability, and smooth operation of steering mechanisms in heavy vehicles and earthmoving equipment. Whether you require fully machined precision components or durable blanks for customized applications, our king pins deliver dependable performance and long service life.

Engineered to withstand extreme loads and continuous movement, our king pins are trusted by global OEMs and aftermarket clients for their superior strength, precision, and consistency.

From raw blanks to precision-finished parts, Fusion Auto Forge provides king pins that form the core of stable, reliable vehicle steering and suspension systems. Built to perform. Made to last.

Why Choose Our King Pin N/M?

At Fusion Auto Forge, we specialize in the manufacturing and export of high-strength Boom Pins designed to deliver reliable performance in heavy-duty construction and earthmoving machinery. Precision-engineered and built to endure high loads and constant movement, our boom pins ensure the secure articulation of boom arms in excavators, loaders, and other hydraulic equipment.

Crafted from high-grade steel and treated for maximum durability, our boom pins offer excellent resistance to wear, impact, and corrosion — keeping your machines operating smoothly even in the harshest environments.

With Fusion Auto Forge, you get boom pins that match the strength of your machines — engineered for efficiency, reliability, and long-lasting performance.

Why Choose Our Boom Pin?

We manufacture and export premium-quality Bucket Pins that are built to withstand the toughest working conditions in the construction, mining, and earthmoving industries. As a critical component in the pivot mechanism of buckets, our bucket pins ensure smooth operation, optimal load handling, and long service life.

Crafted from high-grade alloy steel and precisely machined to meet strict tolerances, our bucket pins offer excellent resistance to bending, wear, and corrosion. Whether for OEM replacement or custom equipment builds, our pins deliver the reliability and performance your machinery demands.

When you choose Fusion Auto Forge, you’re choosing components that are built to last — delivering the strength and accuracy your equipment needs to perform at its best, every time.

Why Choose Our Bucket Pin?

We design, manufacture, and export Loader Pins that meet the highest standards of durability, performance, and precision. Used in wheel loaders, backhoes, and other heavy machinery, our loader pins are engineered to handle high loads, continuous motion, and harsh working environments.

Built from high-tensile materials and processed through advanced heat treatment techniques, our loader pins ensure minimal wear, accurate alignment, and extended service life. Whether you’re operating in construction, mining, or agriculture, our pins deliver consistent, reliable performance.

With a commitment to global quality standards and dependable delivery, Fusion Auto Forge is your trusted partner for loader pins that keep your equipment working harder, longer.

Why Choose Our Loader Pin?

At Fusion Auto Forge, we specialize in the manufacturing and export of premium-grade KPC Pins, engineered to deliver superior strength, durability, and performance in heavy-duty earthmoving and hydraulic systems. Known for their reliability and high load-bearing capacity, KPC Pins are critical in ensuring smooth articulation and secure connections across various types of construction and industrial machinery.

Crafted from high-quality materials and subjected to stringent quality checks, our KPC Pins meet international standards and are trusted by OEMs and aftermarket clients worldwide.

When performance and reliability matter, Fusion Auto Forge delivers KPC Pins that stand up to the toughest tasks — keeping your equipment moving with confidence.

Why Choose Our KPC Pin?